Our process and products are closely monitored by highly qualified team.

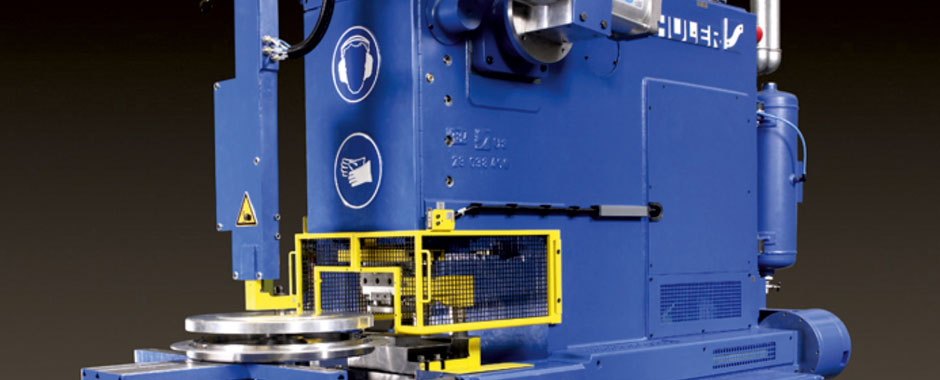

Ujwal is having production capacity of 1000 Tonnes per month, manufacturing stampings ranging from diameter 40mm to 500 mm diameter as per customer's requirement with in-house built tools on highly sophisticated presses passed through strict quality controls.

Tool Designing, manufacturing & maintenance

As a major strength of company , tool room is well equipped & supported by latest designing facilites in-house.

With a good network of sub contactors for special processs of vaccum heat treatment & using inhouse grinding, jig boring & wire cut facilites, company can manufacuture tool of size 1500mm X 700mm.

With efforts of Highly Qualified ToolRoom engirneers, company has manufactured more than 100 High speed progressive tools running with spm of 100 to 300 nos.

Machines like Sodick wirecut & SIP jig boring supports the toolroom very well for manufacturing & maintenance of tools.

Ujwal own tools & customer supplied tools are very well preserved by following way.

- Records of preventive maintenance

- Records of repair maintenance performed

- Die life record monitored

- Performance & other maint issue identification.

You can submit a Quotation Request, uploading all necessary files, via this website.

Facilities at a Glance

Tool Manufacturing & Maintenance

Sodick Wire-cut / Kent Surface Grinder

Rotor Die Casting

Wound Excitor Rotor

Progressive Stamping & Blanking

N25N Notching Machine

Progressive Stamping & Blanking

HD 500T

Slitting

Coil Slitting

Heat Treatment

Heat Treatment

Quality Assurance

Material Testing

Quality Assurance

Process Inspection